B.Pharmacy 4th sem Pharmacognosy Unit 1 Playlist-

B.Pharmacy 4th sem Pharmacognosy Unit 1 Playlist- Model question from Unit 01. Pharmacognosy, B.Pharmacy 4th Semester. You can download these in single PDF by scanning QR or clicking the link-

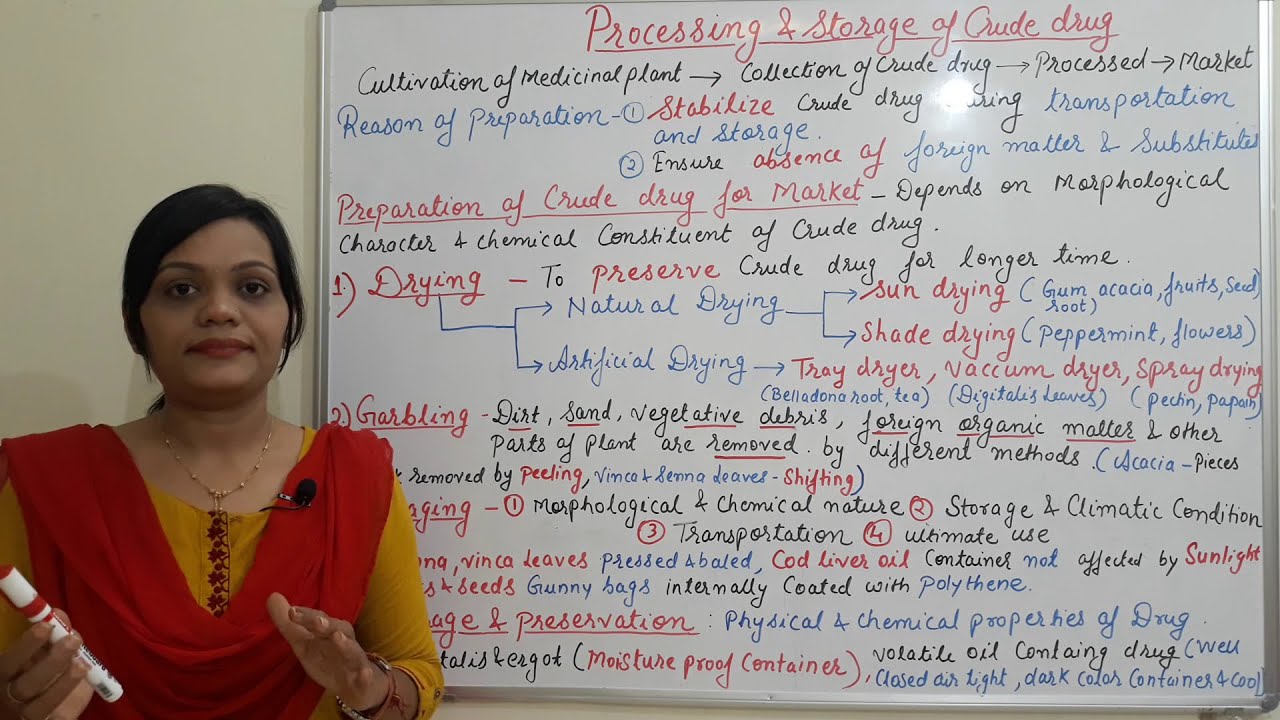

Processing of drug for Market

Harvested or collected raw medicinal plant materials should be promptly unloaded and unpacked upon arrival at the processing facility. Prior to processing, the medicinal plant materials should be protected from rain, moisture and any other conditions that might cause deterioration. Medicinal plant materials should be exposed to direct sunlight only where there is a specific need for this mode of drying.

Drying

By this process we can remove moisture from plant material for :

1- Preventing the Microorganisms growth

2- Facilitating grinding process

3- Inhibiting of some enzymes & reactions which can convert some of the plant constituents from active to in active state .

Method of Drying : -

1- Natural drying - this is done either by :

A) Under the Sun light : used for crude drugs which are not affected by the light and high temperatures ex : Black pepper

B) Under Shade : - for crude drugs which are affected by light & high temperature ex : fruits of Opium in ( Papaver somniferum ).

2- Artificial Drying

This type of drying is made by using the ( Oven ) instrument and by this instrument (the temperature and drying period ) can be controlled , after this step we must make the garbling process in order to remove the external matter ( Other parts of the plant with dirt and any a adulterants added ) , this process can be make during the collection , but it must be make after drying the crude drugs and before packaged .

Storage

Most of the crude drugs are stored at a temperature ( 20 – 25 C ) in closed containers for a period of time depending on the type of these drugs .Storage facilities for medicinal material should be well aerated, dry and protected from light, and, when necessary, be supplied with air-conditioning and humidity control equipment as well as facilities to protect against rodents, insects and livestock. Some medicinal plant materials require specific processing to: improve the purity of the plant part being employed; reduce drying time; prevent damage from mould, other microorganisms and insects; detoxify indigenous toxic ingredients; and enhance therapeutic efficacy.

0 Comments